Saturday, December 27, 2008

http://www.hntgordon.com.au

During our big Christmas road trip we made it to Alstonville on the North Coast of New South Wales - The home of HNT Gordon planes. Despite Australia being a small producer of tools, we are fortunate to have some of the best.

Fortunately for us, Terry Gordon, the plane maker himself, was in the shop when we dropped in. Which was a good thing, as I've always used iron bed planes, the wooden ones took a little getting used to. After a 30min demo, we got the tour of the shop. From wood storage, preparation, shaping, and final finishing. Top bloke that was more than happy to show us around.

Friday, December 12, 2008

Today's the day...

Today's the big day. Delivery of the table.

Once I screw down the top its complete.

Only challenge now is to fit it all in the back of the car... All those years of tetris will finally pay off.

Here's some pics.

When I've got more time I'll do a write up and talk about what I would have improved.

Feel free to post comments or email me any suggestions or comments.

Thursday, December 4, 2008

Rounding Off

While in Sydney, I made it to Carbatec to purchase a lovely 1/8" CMT round over.

Makes the project gentler and a lot nicer to the eye and hand.

Glue up in the kitchen. (Flatter than the shed.)

Wednesday, December 3, 2008

Blogging delay... nothing to do with wood.

It's been an interesting week.

We travelled down to Sydney for my graduation. It was also my wife's birthday which was a good opportunity to go to the "theatre" and saw "My Fair Lady." Which was lovely. Then spent the rest of the week seeing family and friends.

So far so good...but on the way home a new problem developed.

My faithful transportation system... my 2000 model falcon wagon... also known as "hungry hippo"... had a slight problem. And now... It's not feeling too well right now. (No one was injured other than some whiplash that's settled down.)

Saturday, November 15, 2008

Tuesday, November 11, 2008

Leg Joinery

With the top well underway, my energy is diverted to the legs.

The choice of joinery in this case is through tennons, and wedges formed from our secondary wood - rosewood.

As there are curves involved there are a few tricks. My tools of choice for this task is my trusty makita drill with a 1/2" bit, and to keep me on the straight and narrow, a stanley no. 59 dowel jig.

Before getting started, you need mark out the mortise. So that I don't blow out the bottom I've actually removed 1/8-1/4" material on the underside - remember this is curved side will be visible (to thier feet anyway.)

This a twist or brad point bit aim to overlap your holes but drill every second one before the overlap. This technique allows symetrical forces on the bit and helps reduce the change of the bit skipping into the hole next to it.

I then clean the joint with hand tools. Bench chisels remove the bulk of the material but chopping, then paring. Then finally I use a rasp to smooth the inside careful not to roll or damage the edges.

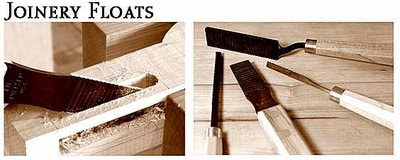

(A side note. I was at the Lie-Nielson site the other day and saw these joinery floats. I know little about them, but assume they work very similar to a rasp, and could be very handy at times. Let me know if you have any experience with them.)

Sunday, November 9, 2008

Rosewood Turnings...

To be honest I'm not really much of a turner. Occasionally however the need arises.

Today, I made about 80cm of 8mm dowel.

The timber is from an old, half burnt, rosewood weatherboard.

I think these will be a very nice touch. More to come.

Tuesday, November 4, 2008

Saturday, November 1, 2008

Wood shopping...

Boutique Timbers

Once you graduate from Bunnings bought Radiata Pine you’ll want to explore the world of Australian Hardwoods and Softwoods. I’m fortunate enough to have a good local timber merchant. Mal Ward of Boutique Timbers has always offered me good variety (I've purchased from him Tas. Blackwood, Tas. Mrytle, Huon Pine, Silky Oak, Northern Silverash, River Redgum, Jarrah...) all at a good price. His small mill trades mostlyin slabs rather than boards, and all the wood I’ve purchased has been air dried on his property. He travels to a variety of woodshows around the country. If you come across him mention my name.

My purchase

After discussing the project, quantity of , and my budget - Mal showed me a few timbers and we eventually deciding on Coastal Blackbutt. Blackbutt is a very heavy and dense wood akin to Red River Gum (my last large project.) Why Blackbutt? Although a relatively plain wood, I chose it because it is grown locally (you see it everywhere around here) and I liked that. I also wanted something strong enough to handle the curves I want to make. One thing I wasn’t prepared for was – although my tools don’t seem to mind it, my back does, this is a really heavy wood.

4 boards, 3m long, all wedge shape 350mm-400mm, and 50mm thick – total $300.

Rough marking, making sure all the parts will fit.

The rough tabletop.

Benches, stretches and everything else.

Subscribe to:

Comments (Atom)

.jpg)

.jpg)

.png)